Hot key words: Diamond crushing material Diamond shaping material Diamond powder Ultra sharp honeycomb diamond powder

PRODUCTS

Address: East side of North High Speed Railway Bridge, Lulu Road, Xiangcheng District, Luohe City

phone:+86-395-6161691

Mobile phone:+86-13903959561

Fax:+86-395-3168861

Mailbox: luohetailong@163.com

Honeycomb diamond powder

product description

Product description:

Ultra-sharp honeycomb diamond micropowder is a new type of abrasive material with high-quality diamond as raw material and treated by special process. The edge of diamond particles is passivated and honeycomb-shaped, which effectively prevents deep scratches on the surface of the workpiece. Compared with the traditional diamond micropowder, it has the advantages of high grinding efficiency, low surface roughness of the workpiece and less residual particles on the surface of the workpiece. Suitable for polishing and surface treatment of precision industrial devices such as hard disks, magnetic heads, semiconductor materials, gemstones, diamonds, ceramics, etc.

Product features:

★ Strong cutting force: The surface of the particle has a large number of sharp cutting edges, and the cutting force can reach 2-4 times of the single crystal diamond powder;

★ High polishing precision: the surface of the single crystal diamond micro-powder particles is large and hard, which is easy to produce deep scratches. The surface of the polycrystalline diamond micro-powder particles has small cutting edge and low hardness, and the Ra value of the surface of the workpiece after polishing is significantly reduced.

★ Strong holding power: the surface of the particles is rough, and it is more firmly combined with the bonding agent, which can significantly improve the holding power of the abrasives in various diamond products and improve the service life.

Available granularity:

| 2-4 | 3-6 | 4-8 | 5-10 | 6-12 | 8-16 | 10-20 | 15-25 | 20-30 | 22-36 | 30-40 | 36-54 |

| √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ |

Note: The table shows the general granularity, and other granular products can be provided according to customer requirements.

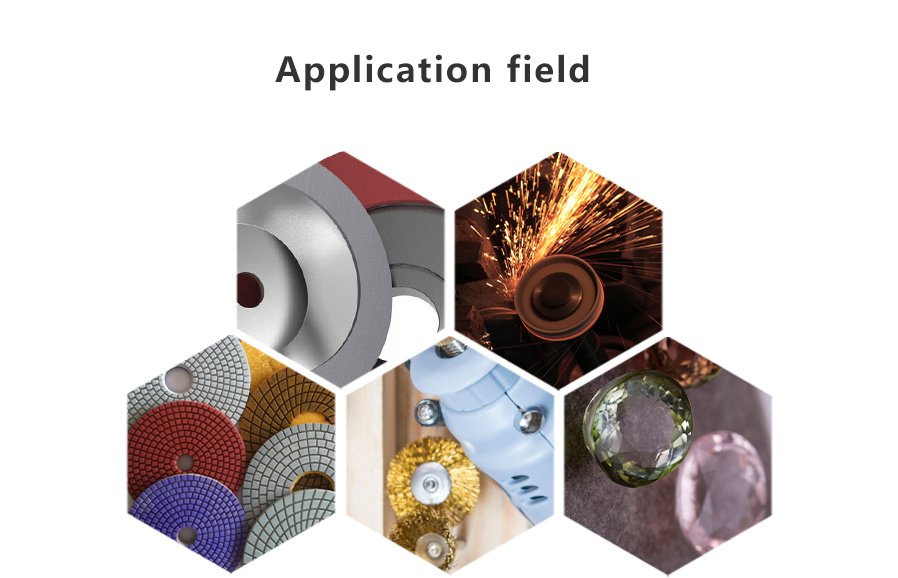

Application areas:

★ Precision grinding and polishing of SiC, Al2O3 and other wafers;

★ Grinding and polishing of ceramic materials;

★ Precision grinding and polishing of metal materials such as stainless steel and aluminum alloy.